Tire Scan Cube | TSC

Automatic tire documentation for tire hotels and industrial tire storage

Automatically document thousands of wheels per day with the Tire Scan Cube

The Tire Scan Cube enables the automated capture and documentation of entire tire stacks – quickly, efficiently, and without manual handling. In less than 60 seconds, a complete stack or set of wheels is fully measured and digitally recorded.

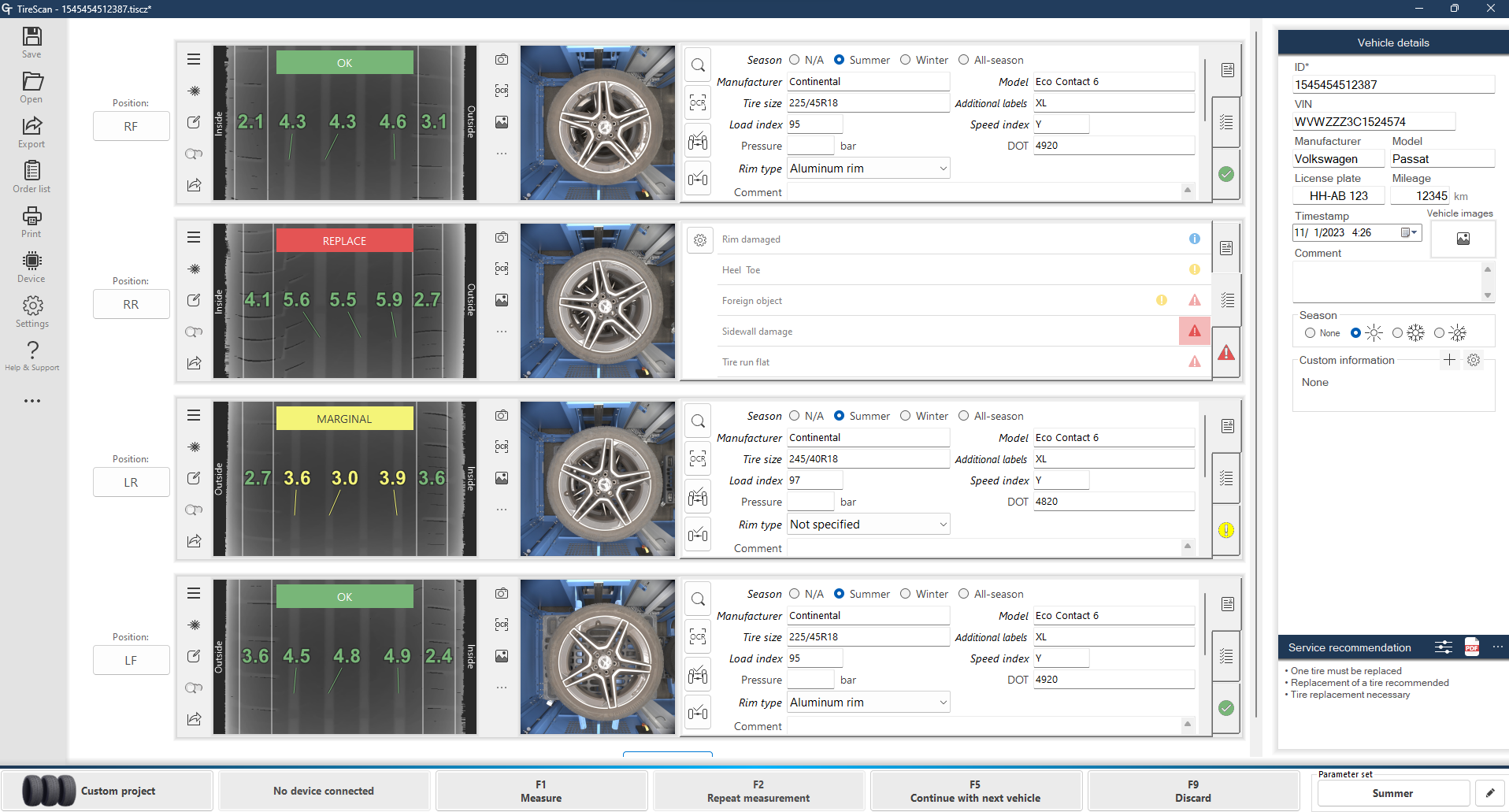

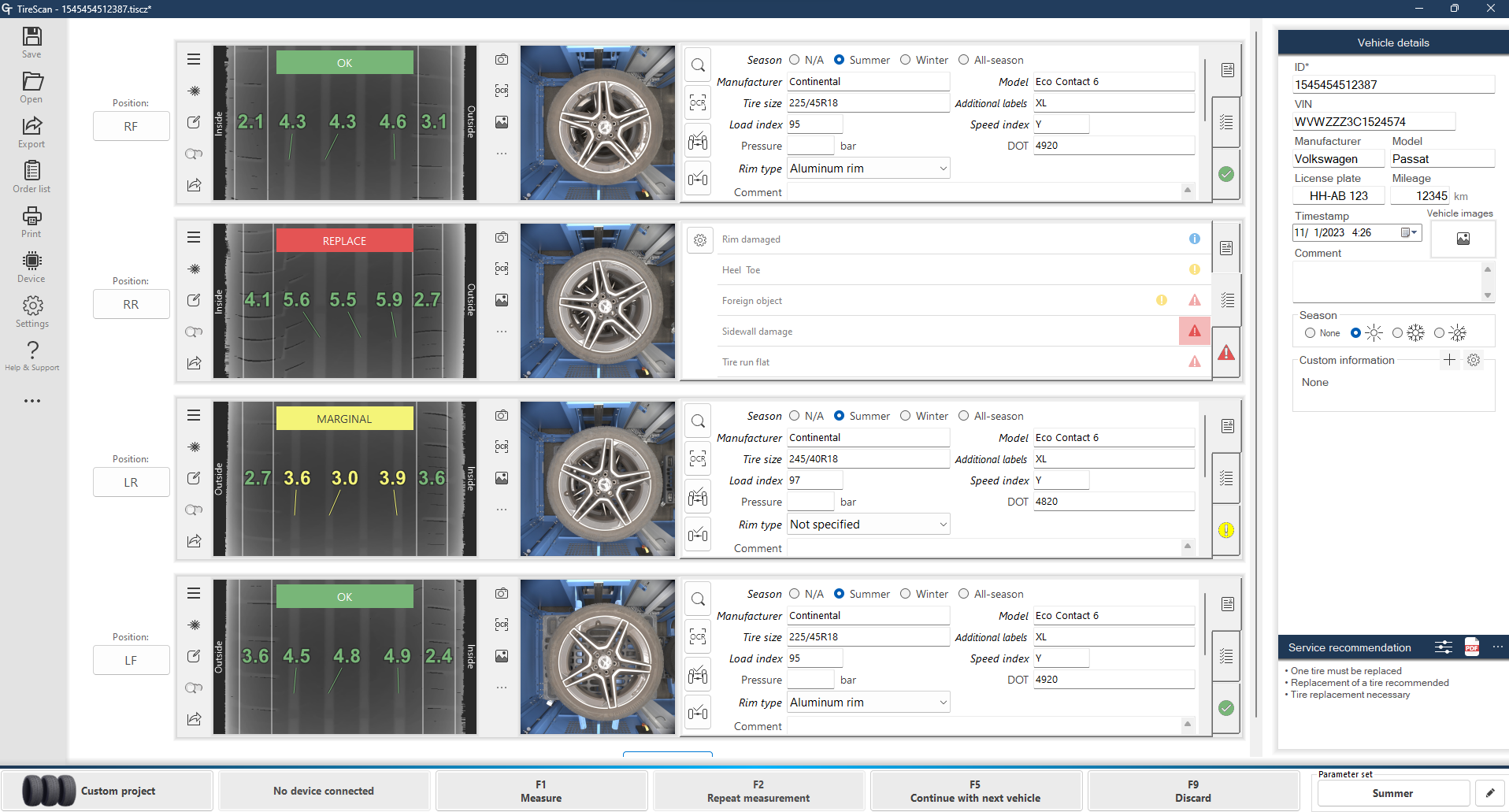

The process is remarkably simple: tire stacks are pushed directly into the system without manual lifting. A precision laser scans the tread and measures the depth across the entire width – reliably and accurately. In addition, wear is analyzed and incorporated into a clear green-yellow-red tire condition rating.

At the same time, a high-resolution camera captures each individual wheel, automatically detecting all relevant tire data using AI-based image recognition. This includes manufacturer, model, tire size, load index, speed index, DOT, OE code, run-flat/seal/silent technologies, and many other identifiers. The result is a seamless, digital tire documentation – more efficient than ever before.

Automatic tire documentation with 3D tread measurement and tire data capture

The Tire Scan Cube is operated and controlled directly on the device via an integrated monitor.

All recorded tire data – tread measurements, images, reports, and more – are collected and stored centrally in one location or file using the Tire Scan analysis software.

Thanks to integrated interfaces, the data can be seamlessly transferred into your inventory management system, such as RESY, and used immediately.

Automatic tire documentation with 3D tread measurement and tire data capture

The Tire Scan Cube is operated and controlled directly on the device via an integrated monitor.

All recorded tire data – tread measurements, images, reports, and more – are collected and stored centrally in one location or file using the Tire Scan analysis software.

Thanks to integrated interfaces, the data can be seamlessly transferred into your inventory management system, such as RESY, and used immediately.

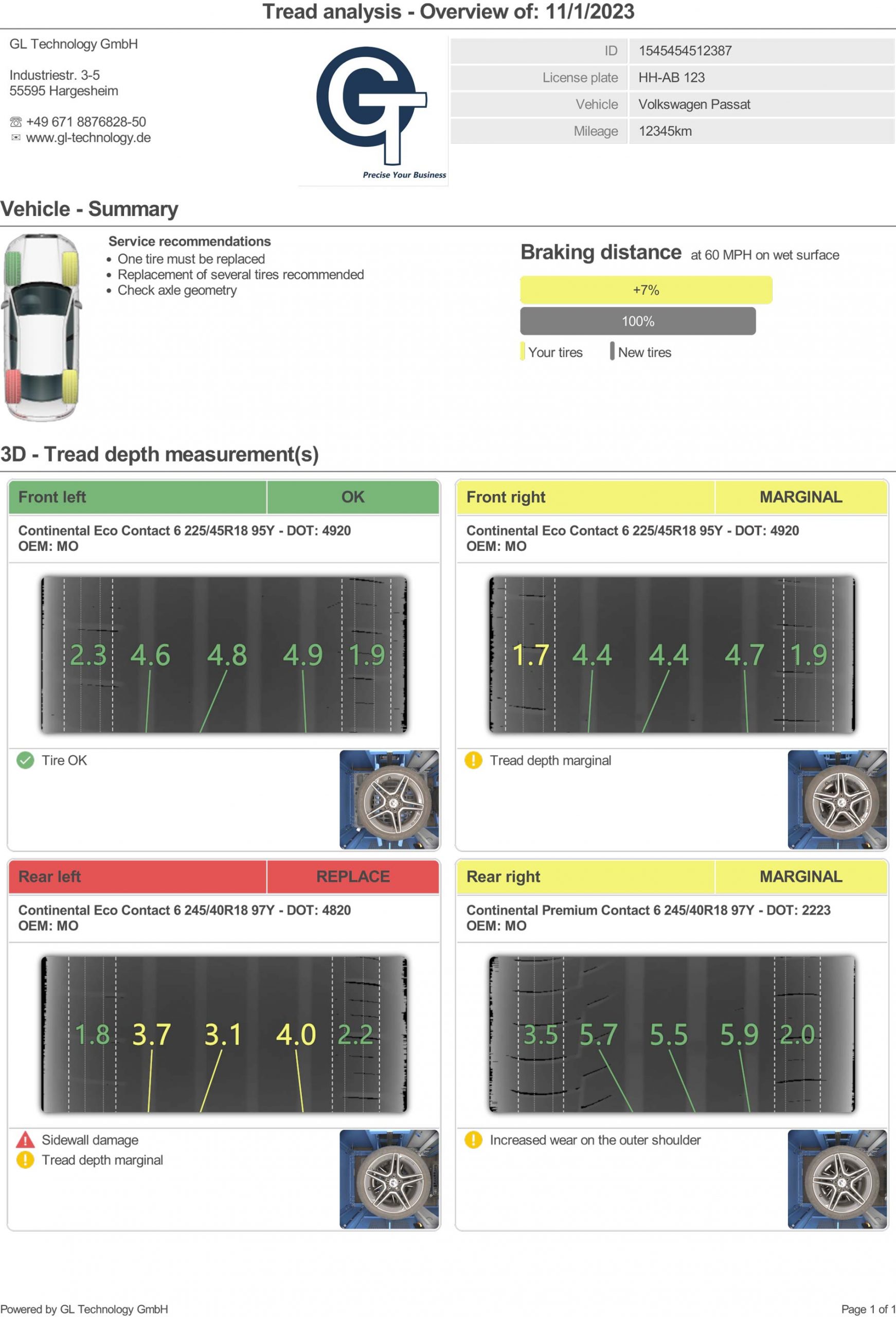

PDF Overview with clear service information

Should a tire be replaced or not? Just like in the Tire Scan software, the PDF overview clearly shows the condition of each individual tire. In this sample overview, you can see at a glance:

Green: The front left tire is in good condition.

Yellow: The front right tire has a borderline tread depth of 1.7 mm at the shoulder. The rear right tire shows increased wear on the outer shoulder compared to the inner shoulder, which is also classified as borderline.

Red: The rear left tire has borderline tread depth and a damaged sidewall. Replacement of this tire is recommended.

Of course, the threshold values used can be individually configured to make the service recommendations visually clear and easy to recognize.